SIAD compressors can compress all types of gas: inert, oxidising, toxic, explosive and corrosive.

Compressors are complete with electric motors, air or water heat exchangers, instrumentation, electrical panels and filters.

- Pulsation, acoustical, torsional, bending analysis.

- Finite elements structural verification.

- Fluid-dynamic verification.

- Fatigue calculation.

- Measurement and verification of vibration, ultrasonic, thermography, radiography.

- Chemical, physical and metal particles oil analysis.

- 3D modelling, static elastic FEM analysis, infinite life fatigue analysis;

- Elastic bodies motion of the complete frame, static elasto-plastic FEM analysis;

- Multiaxial fatigue analysis with the algorithm of Dang Van or Brown – Miller – Morrow.

- The gas paths are studied by the computer with most advanced CFD software with the aim to reach at the same time a small clearance volume, for a greater volumetric efficiency, and large and well profiled passages for low pressure losses.

- Refinery

- Petrochemical

- Chemical

- Energy

- Food

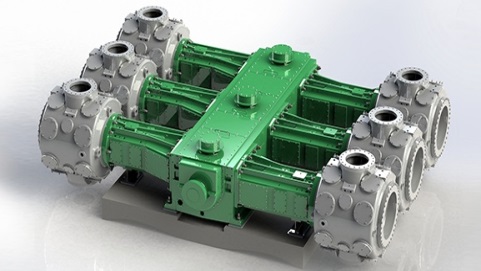

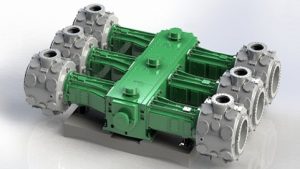

Stage: 1-2-3-4-5-6

Maximum Suction Volume: 90 000 mᵌ/h (37 950 acfm)

Maximum Power: 8 700 kW (11 850 HP)

Maximum Delivery Pressure: 600 bar (a) (8 700 psig a)

Types of Cylinder Configuration: Vertical, V, W, Horizontal

SIAD also offer Oil-free Reciprocating Compressors for PET Bottle blowing